Bright Ideas – 2024

Back to Competitions | Bright Ideas is Kingston University’s annual competition designed to give students the opportunity to gain more confidence in ideation, developing and presenting an idea. Open to any students of any faculty at any level, the competition allows students to attend innovation workshops, have an idea evaluated and win a prize as they start their entrepreneurial journey. |

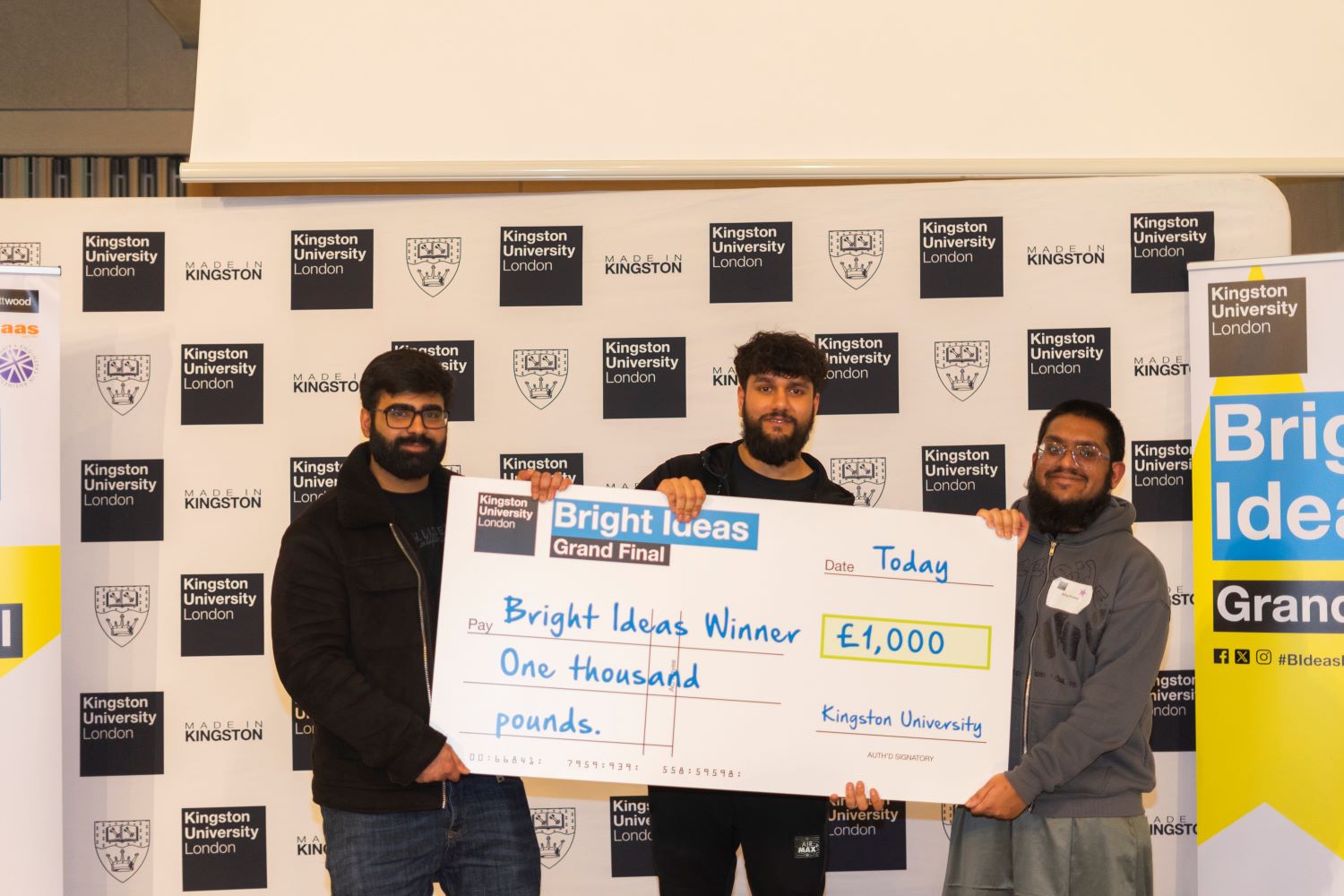

Category one - first place: Alloy Armour

Alloy Armour is a cutting-edge technology that is transforming alloy wheels’ resistance to harsh road conditions. This innovative product is a self-adhesive rubber compound with a unique gel designed to absorb and lessen the effects of potholes and other road irregularities, extending the life and functionality of car wheels.

The identified problem revolves around the vulnerability of alloy wheels to damage from road hazards, such as potholes, impacting the overall driving experience and leading to costly repairs. The need is for a proactive solution that preserves wheel integrity and performance. Alloy Armour prevents alloy wheel damage caused by unforeseen traffic accidents in a proactive manner. Its protective inner layer greatly lowers the possibility of cracks, bends, and structural problems, averting expensive repairs and guaranteeing a safer, more comfortable ride even on rough roads.

Students:

- Navid Rehman – Civil and Infrastructure Engineering

- Ikraam Choudhry – Civil and Infrastructure Engineering

- Sufiyan Hussain – Civil and Infrastructure Engineering

- Ahmed Khierawi – Civil and Infrastructure Engineering

- Octavia Wright – Civil and Infrastructure Engineering

Prize awarded: £1,000

Category one - second place: Enhancing Sustainability at London Heathrow Airport by Harvesting Sound Energy

With 380,317 aircraft movements in 2022, London Heathrow Airport (LHR) is the second busiest airport in Europe. As part of the aviation community, LHR is habitually stigmatised as a leading contributor of numerous pollutants, one of which is noise that detrimentally affect people’s health. At present, all aircraft noise at LHR is

unharnessed sound energy that transfers to the atmosphere as heat and motion.

To meet the goals set out in the Heathrow sustainability strategy 2.0, noise pollution and carbon emissions on the ground are to be reduced by 45% of 2019 levels, by 2030. A need exists to produce a sound harvester for LHR so that unwanted noise can be converted to electrical energy, providing a sustainable power source, whilst also reducing pollution.

Developing a sound harvesting system, the product aims to convert ambient noise surrounding the runway into electricity which would be utilised as the primary source of power for the runway lights. A piezoelectric transducer subjected to soundwave vibrations will generate a voltage directly proportional to the wave intensity, which would be rectified to direct current and stored in four supercapacitors. Once the light is commanded on, a voltage regulator will ensure a stable supply to the load. The self-powered light unit will reduce LHRs energy consumption by approximately 587,620 kWh/year. Thus, an estimated cost saving in the region of £148,000 yearly, possibilities of utilising excess harvested power around LHR, and reduction in noise pollution, add significant value to the operation.

Student:

- Vladislav Trayanov – MSc Aerospace Engineering

Prize awarded: £250

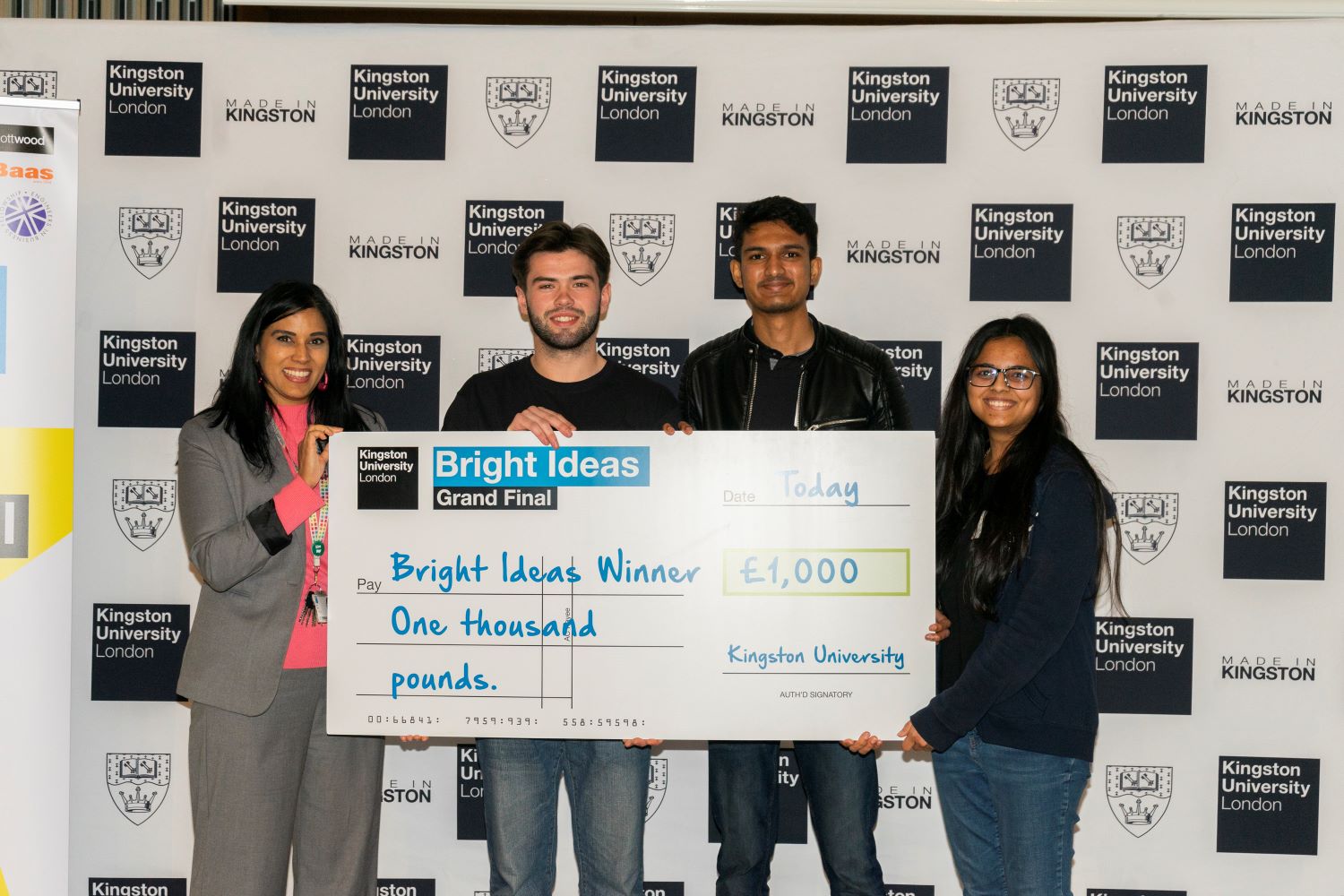

Category two - first place: Excelsior

The use of the pushback tugs, engines during taxi and auxiliary power unit, all contribute to the use of fossil fuels which all harm the environment. To envision a more sustainable future in aviation, Excelsior hopes to bring net zero closer. On top of this, the team addressed other problems, such as airfield noise as well as danger while working in and around aircraft due to the risk of engine ingestion.

This innovative system is designed to leverage the remarkable capabilities of ultracapacitors, providing rapid charging and discharging to meet the demanding power requirements of critical processes such as pushback and taxi. Additionally, a seamless integration with onboard batteries serves as a redundancy measure, ensuring optimal performance and safety throughout the operational lifecycle.

The system includes ultracapacitor technology, induction motors, redundancy with onboard batteries, dual motor configuration, pilot-controlled operation, and integration of sensor and camera technologies.

Students:

- Cameron Solly – Aviation Operations with Commercial Pilot Training

- Hesara Senanayake Mudiyanselage – Aerospace Engineering

- Rhea Paresh – Aviation Engineering

Prize awarded: £1,000

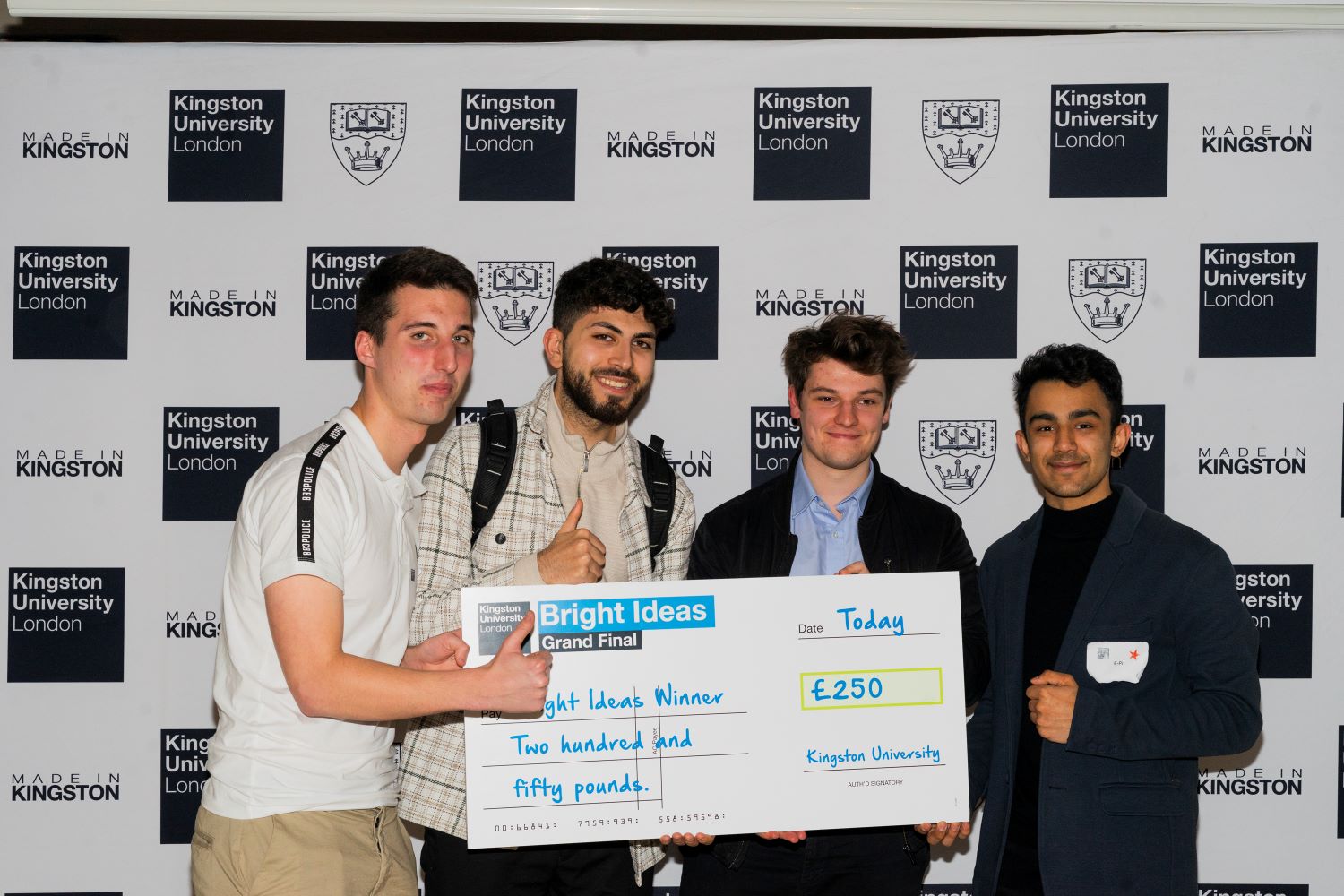

Category two - second place: E-Pi

Almost half of British adults suffer from at least one allergy, with over ten million people suffering from more than one. This costs the NHS circa £900m a year and around 30 people a year die from a severe allergic reaction.

The Epi-pen has been highly effective but is easy to forget and it is sometimes too late by the time symptoms have presented themselves. The auto-injector will be able to save the NHS money, due to the reduction in epi-pens and hospital admissions, on top of this reducing the amount of treatments prescribed to patients which currently stands at 10% of the NHS prescribing cost. Also, reducing the use of NHS resources as an ambulance will not need to be called out.

Students:

- Alex Pullan – Aerospace Engineering and Astronautics with Space Technology

- Oscar Vidler – Aerospace Engineering and Astronautics with Space Technology

- George Gaid – Aerospace Engineering and Astronautics with Space Technology

- Aran Raja – Aerospace Engineering and Astronautics with Space Technology

- Cyprian Gut – Aerospace Engineering and Astronautics with Space Technology

Prize awarded: £350 (including Golden Ticket award)

Positive feedback

Bright Ideas is an essential part of our Engineering courses. It helps students to understand the real need for innovation skills and an enterprising mindset in the engineering profession, and to develop the confidence and skills to contribute. We are proud to be helping our students to develop their future skills. We are delighted that our students are able to take advantage of the help which EIBF offers, and very grateful for the continued partnership.

Amir Alani

Dean of Engineering

Computing & Environment and Pro-Vice Chancellor

Kingston University